This post is also available in:

Today, Arctic areas are attracting much attention due to the large oil and natural gas deposits located there. As much as 13% of the Earth’s unexploited oil reserves and 30% of natural gas reserves may be located in Arctic areas. The energy industry’s largest projects to build gas and oil distribution networks are essentially based on steel construction and welding technology.

Weatherproofing welding equipment for better outcomes and working conditions

For example, the oil and gas pipelines in Siberia, Russia, need to be built through marshlands that are difficult to traverse. This must be done in the winter because the ground must be sufficiently frozen to support all of the necessary machinery. Welding can only be successful in Arctic conditions if the working conditions are tolerable. Depending on the weather, the welding process, and the application, different protection levels are used, ranging from completely unprotected welding sites to air-conditioned and heated cubicles.

For MMA welding in dry weather, it may not be necessary to protect the welding site at all (Figure 1). MIG/MAG and TIG welding should always be done in an area protected from wind, rain, and snow. Protection can be provided by various types of tents (Figure 2) or even heated welding cubicles (Figure 3). A range of different welding protectors can also improve the welder’s working conditions. Without a heated welding cubicle, the welder can easily begin feeling cold, and the visor on the welding helmet can fog up.

Effective preheating can optimize welding procedures and prevent condensation

Special attention should always be paid to preheating before welding in arctic conditions. Firstly, the welding procedure specification determines the preheating temperature. With thinner material strengths and non-alloy steel, this is typically room temperature. With thicker materials and alloy steel, the preheating temperature may be 100°C or more. The second reason for preheating is the condensation of water on cold surfaces. The groove and the surrounding area, as well as any backing, must also be cleaned and dried before welding.

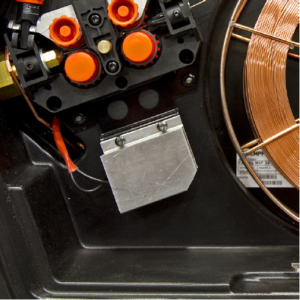

In cold conditions, moisture can easily condense on the surface of the filler material. The welding electrodes should be stored in an electrically heated electrode store. For MIG/MAG welding, it is advisable to use a cabinet heater in the wire feeder to ensure the filler material remains dry.

Studying cold tolerance of welding equipment to guide product development

Kemppi states the operating temperature range for its welding equipment in the user’s manual. The minimum temperature range is between -20°C and +40°C. However, Kemppi’s equipment is also used in Arctic areas, where the temperatures may be substantially lower.

Over the years, the cold tolerance of the devices has been studied in various conditions. Kemppi has premises including a cold room and separate freezers for this purpose at its site in Okeroinen, Lahti, Finland. They enable welding components such as tubes, cables, and mechanics to be tested at temperatures as low as -60°C.

Practical experiments have also been conducted in Arctic areas. In the winter of 2013, Kemppi took several ready-to-operate welding units to Siberia, Russia, for field testing. They were tested at temperatures of -46°C. At such low temperatures, welding is a challenge for the welder as well as the equipment. For example, the rubber components on buried cables, torches, and interconnection cables stiffen due to the cold.

Results from such studies are utilized in product development work when selecting materials for new products. For example, alternate materials have been selected for new buried cables and torches to ensure that they are better at withstanding colder conditions.