Robotic manufacturing technology is more capable than ever. To see how it impacts the welding industry, let’s start by taking a closer look at some of the important trends and key considerations for anyone thinking about investing in welding automation.

Why is welding automation important?

It’s getting harder to find welders

As production requirements change rapidly in today’s world, manufacturers are having trouble finding the right talent at the right time, and traditional blue-collar tasks are becoming less appealing to younger workers. It is difficult to find welders now, and it could be even more difficult in the future as workforce demographics change.

Flexible manufacturing is the new normal

Global economic trends shift quickly these days. As a result, production needs have become more and more unique – if a manufacturer can’t adapt and offer effective offline programming for small welding batch sizes, it is likely that they will lose business to their competitors. Customers want flexible manufacturing capabilities.

Smaller margins

Competition is fierce. As margins continue to shrink, investing in welding automation technology sets you up for long-term success by lowering production costs while also giving you an effective way to increase production capacity quickly.

How will welding automation change manufacturing?

Welders must adapt to new roles

Demand for robot welding operators will grow, and using offline programming to optimize welding processes will become a critical core skill. In general, welders must shift from manually applying specialized welding skills to embracing a hybrid role that requires system-level knowledge. The ability to move between roles will be key – the person planning the integration might also be the one doing the offline programming.

Expert welding knowledge is still required. In fact, the best candidates for these new welding automation roles are often experienced welders who have a deep understanding of the conditions and parameters that influence weld quality.

How do you train welders for this new way of working? It is important to note that companies that make robotic manufacturing equipment typically offer in-depth training and support for getting up to speed with automated welding processes. The aim is to make workers comfortable moving between roles while emphasizing system-level knowledge to achieve synergy between software and hardware.

Technology is everywhere

Virtual tools will make transitioning to automated welding much easier – virtual reality is already being used to program welding robots, and it’s possible to go “inside” a robot welding cell with off-the-shelf VR glasses. VR allows you to “move” things around and check positions to grasp and optimize an automated welding system fully.

This is a huge shift away from a coordinates-based approach. Offline programming has been around for a while now, but VR raises the bar dramatically by allowing you to test configurations without actually setting up equipment. This approach taps into the skills of more visually oriented people while offering the technology that attracts a younger demographic group to welding. In fact, trade schools are actively embracing virtual reality to match the interests and expectations of younger people.

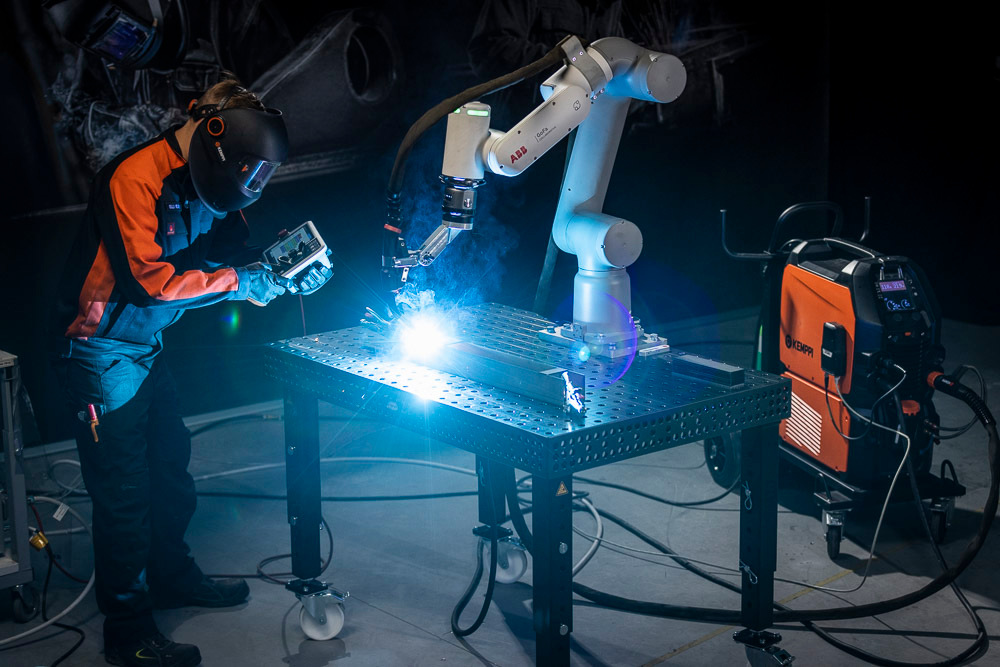

Cobot welding is a great place to start

Welding automation is often associated with large robotic systems, but recently, we have noticed that demo session requests for cobot welding solutions are on the rise. Cobot solutions augment the abilities of a welder by working alongside him or her to automate important tasks. It is easy to use, and the programming is straightforward.

The ROI for cobot solutions is shorter and it’s a good way to introduce robotic welding solutions into the workplace. Younger workers are interested in collaborative robots, and cobot solutions can also be used alongside fully robotic systems.

Take a look at Kemppi’s Robotic welding solutions and Cobot welding solutions.