This post is also available in:

Robomatik offers welding design, installation and training, while also professionally installing and integrating Kemppi welding equipment. They are a growing company that thrives together with Kemppi.

The quality of Kemppi welding equipment is known on the shop floor and in the hands of experienced welders. To ensure that the customer gets the full power and benefits from good welding equipment, Kemppi’s in-house expertise is backed up by a good network of partners.

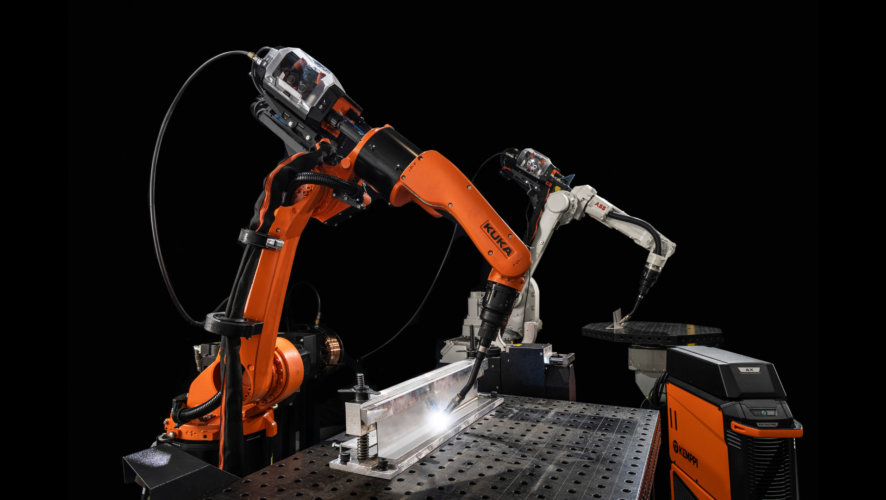

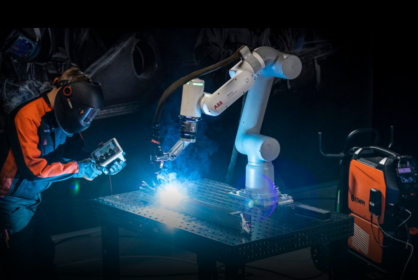

One of the companies in the network is Robomatik Oy, which operates from Vilppula, Finland. Its main products are the design and implementation of welding robots and equipment, processing tables, and welding jigs. Robomatik’s services also include programming, training, installation, maintenance, and repairs. “We have everything you need for robotic welding,” says Jani Matikainen, Managing Director.

Matikainen has been working in welding robotics for more than 20 years. Early in his career, he worked as a welder. “My background is very useful because my personal knowledge allows me to answer customers’ questions and welders’ practical problems.”

Working together benefits everyone

Robomatik has been operating in its current form for more than five years. The company’s turnover has grown steadily, and the cooperation with Kemppi has had a clear impact on Robomatik’s operations and growth. “Selling Kemppi’s products and Kemppi’s trusted brand have expanded our customer base. We are an official dealer of Kemppi, which increases the number of requests for quotations for robotic welding systems. Especially in Finland, the domestic presence is a clear advantage.”

In addition to Matikainen, Robomatik currently has three employees and a large partner network of designers, electricians, and other subcontractors.

Matikainen’s cooperation with Kemppi started on a personal level almost 15 years ago. In that time, Matikainen has delivered Kemppi welding equipment to over 100 worksites. Robomatik has also installed dozens of Kemppi power supplies for automated welding. The outlook for the coming years remains positive. “I can always count on Kemppi’s support in every matter. Kemppi also listens openly to the robot integrator’s experiences and development suggestions. This way, we can develop and improve both the equipment and the customer experience together,” says Matikainen.

AX MIG Welder – the ideal robot welding system for the integrator

One of the most recent results of Kemppi and Robomatik’s cooperation was the integration of Ocotec‘s welding robot in Oulu with a Kemppi AX MIG Welder. Matikainen is familiar with Kemppi’s machines, and it is easy for him to list the strengths of the AX MIG Welder.

“From the integrator’s point of view, compared to other power supplies, the AX is really easy to use and quick to install. Where many other machines take at least a full working day to install, the AX MIG Welder usually takes just a few hours.”

Above all, fast integration saves the customer time.

“For the customer, it is essential that production interruptions are as short as possible,” says Matikainen.

From the user’s point of view, the AX MIG Welder user interface stands out.

“It is clear and easy to use and works on all devices, i.e. phone, tablet, or laptop. Special programs such as MAX Cool and MAX Position, as well as the welding features and adjustability of the device, are its best features.”